DBS Regenerative Festival 2025

DBS Rengerative Festival x Milli Mycomaterials

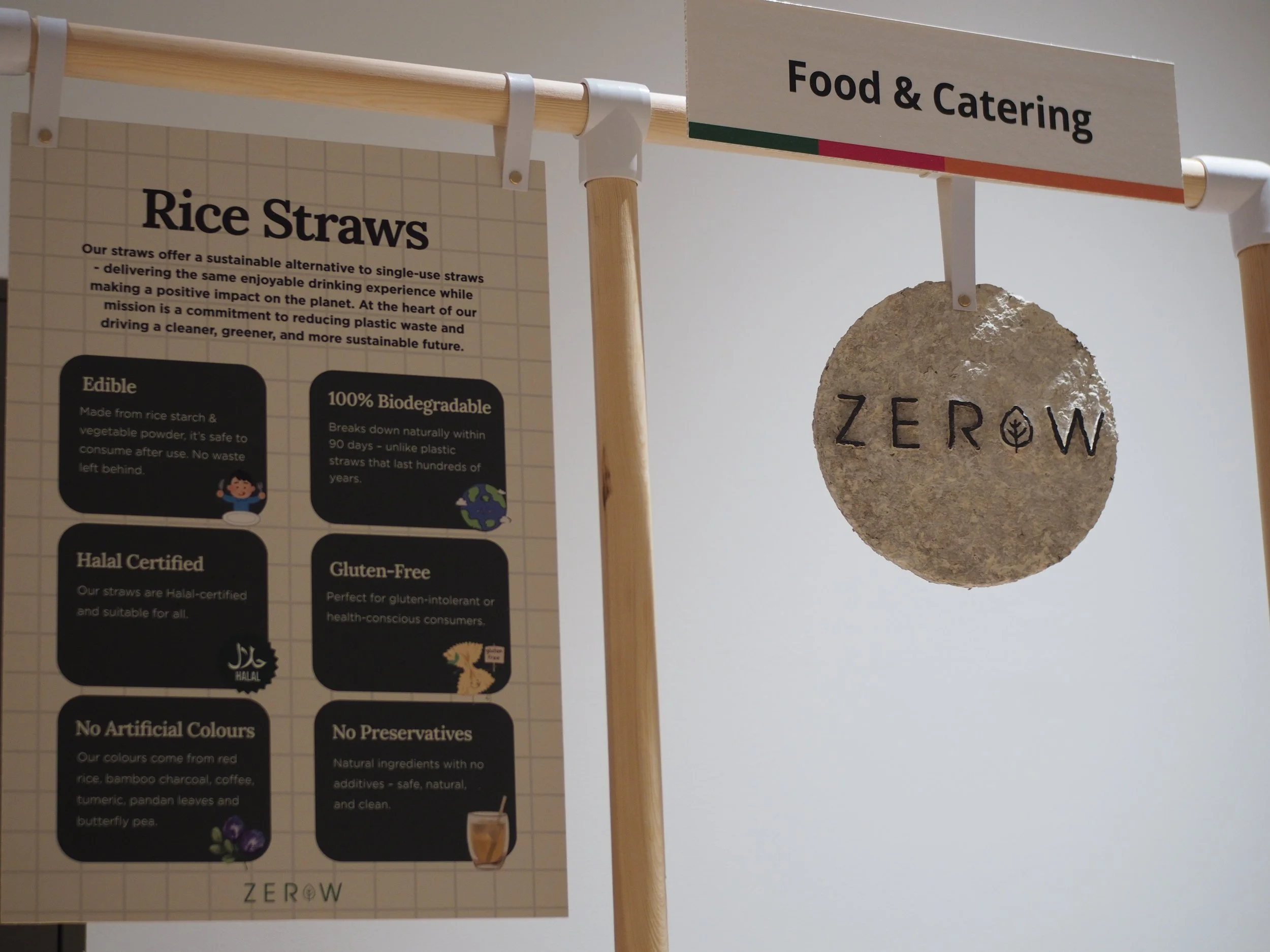

DBS Regenerative Festival is where bold ideas meet real-world action, an initiative by DBS Bank to raise awareness, inspire, and connect with stakeholders in regenerative business practices. Milli Mycomaterials is proud to have been yet another supporting brand partner of the Regenerative Festival, for the second year running!

Rethink, Reimagine, Restore For a Better World.

It was a dynamic day of discovery and connection, where we got to meet, greet and explore innovative circular products & green solutions from sustainable enterprises and SMEs. We’d like to thank DBS for commissioning Milli Mycomaterials to create sustainable mycelium display signs for all participating brands and vendors at the event!

Made out of our Mycelium technology, each brand had their logo and name grown on waste substrate and turned into a cool display sign of their businesses, which was hung in front of their respective booths. Overall, it was a super fun and fulfilling experience having our Myco display signs come to life, from design to production.

What Goes Into Making Mycelium Products?

This got us thinking, why not show the process of what goes into making our signature mycelium products? Sharing and imparting knowledge related to what we do, has always been an important part of what we’re trying to achieve at Milli Mycomaterials, which is building trust and curiosity around bio-materials.

Our mission is to show the potential and strengths of mycelium based solutions and accelerate the transition toward sustainable building materials and circular design. To educate people about mycelium as a viable, renewable alternative as it helps reduce dependency on traditional synthetic options that are a major source of carbon emissions, energy intensive to produce and harm our environment.

It Begins With Mycelium.

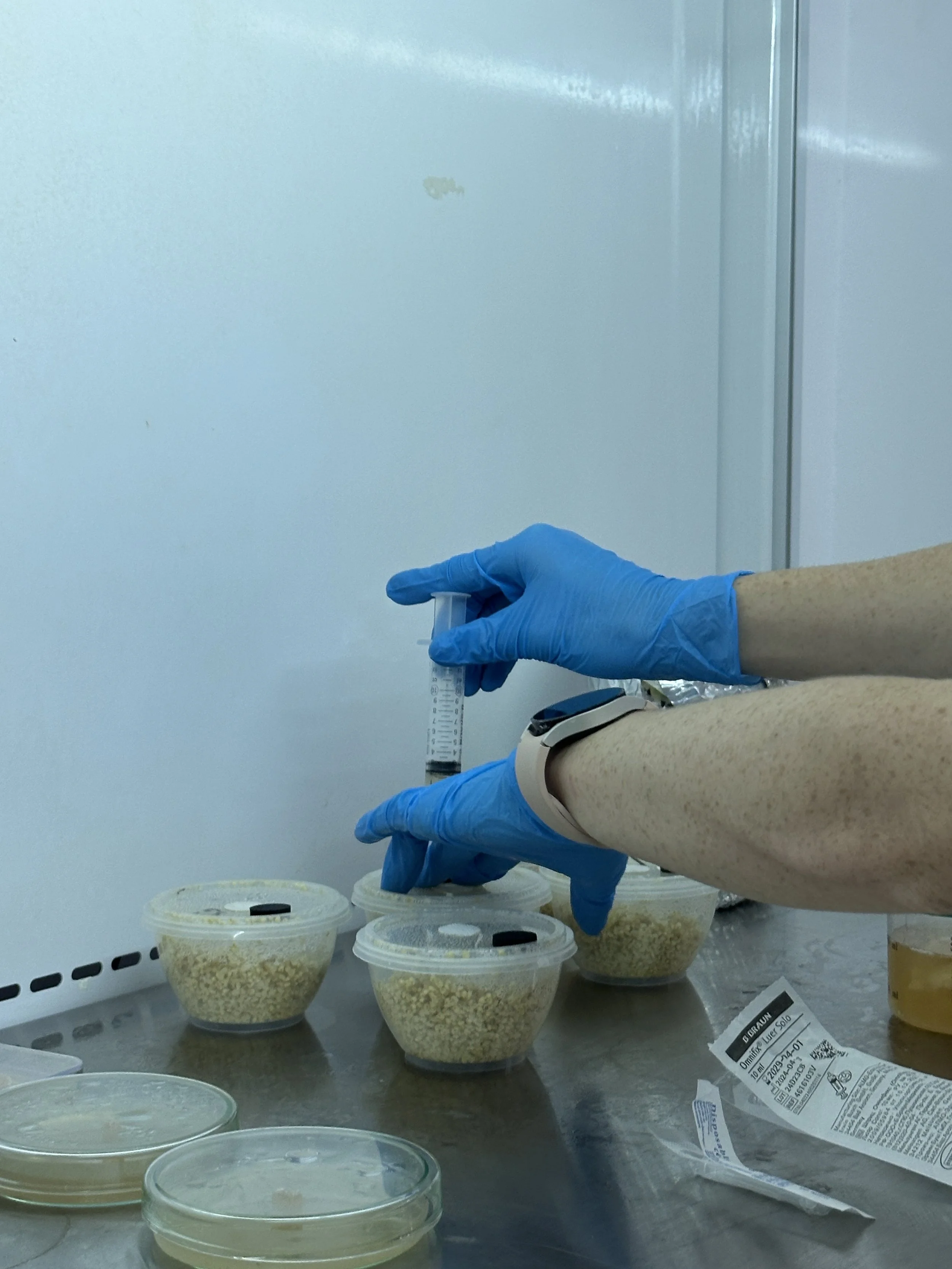

The process of cultivating mycelium-based materials begins in the lab, we select an appropriate fungal strain suited to our intended application. Once the strain is selected, it is inoculated with grain then introduced to sterile organic material such as waste streams like, sawdust, straw or hemp, which provides a nutrient rich base for growth.

Then in our production facility, we prepare the substrate carefully. It is mixed, moistened, pasteurized and sterilized to eliminate competing micro-organisms ensuring optimal conditions for mycelium colonization. This preparation stage is critical, as it balances moisture, nutrient content, and aeration. All of which promote healthy, even growth that forms the foundation of strong, uniform mycelium composites.

From Waste to Worth.

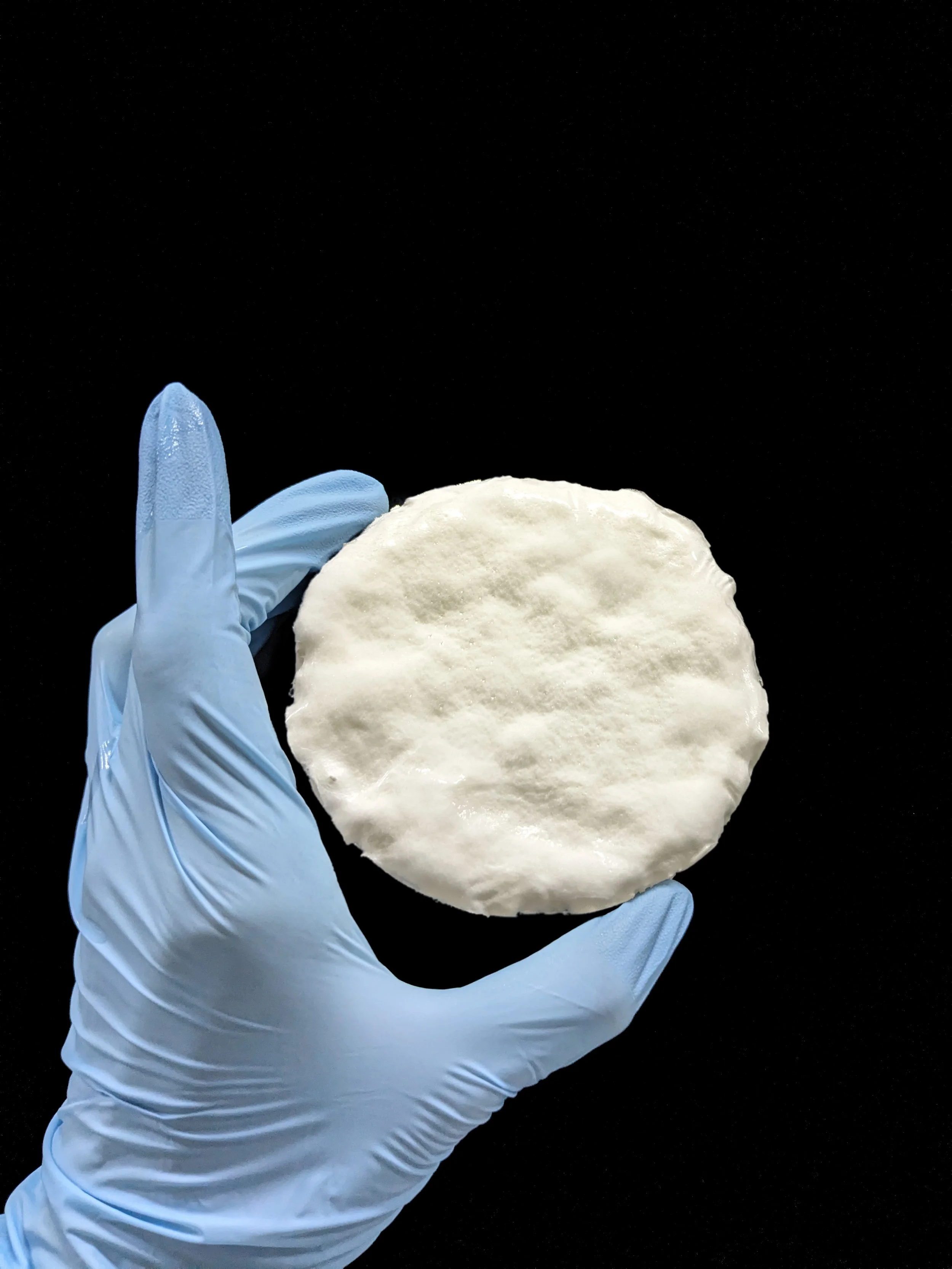

Typically, mycelium based bio-materials are grown by allowing fungal mycelium to colonize an organic substrate inside a mould. During this stage, the mycelium grows through the substrate within the mould. Retaining humidity and creating a microclimate that encourages even colonization throughout the mould.

This 1-2 week process binds the substrate into a solid composite, which results in a material that has a extremely low carbon footprint, non toxic, is fully bio-degradable and 100% compostable. At the end of their lifespan, they can be safely broken down and returned to the soil, feeding the surrounding microbial ecosystems rather than polluting them.

Milli goes further.

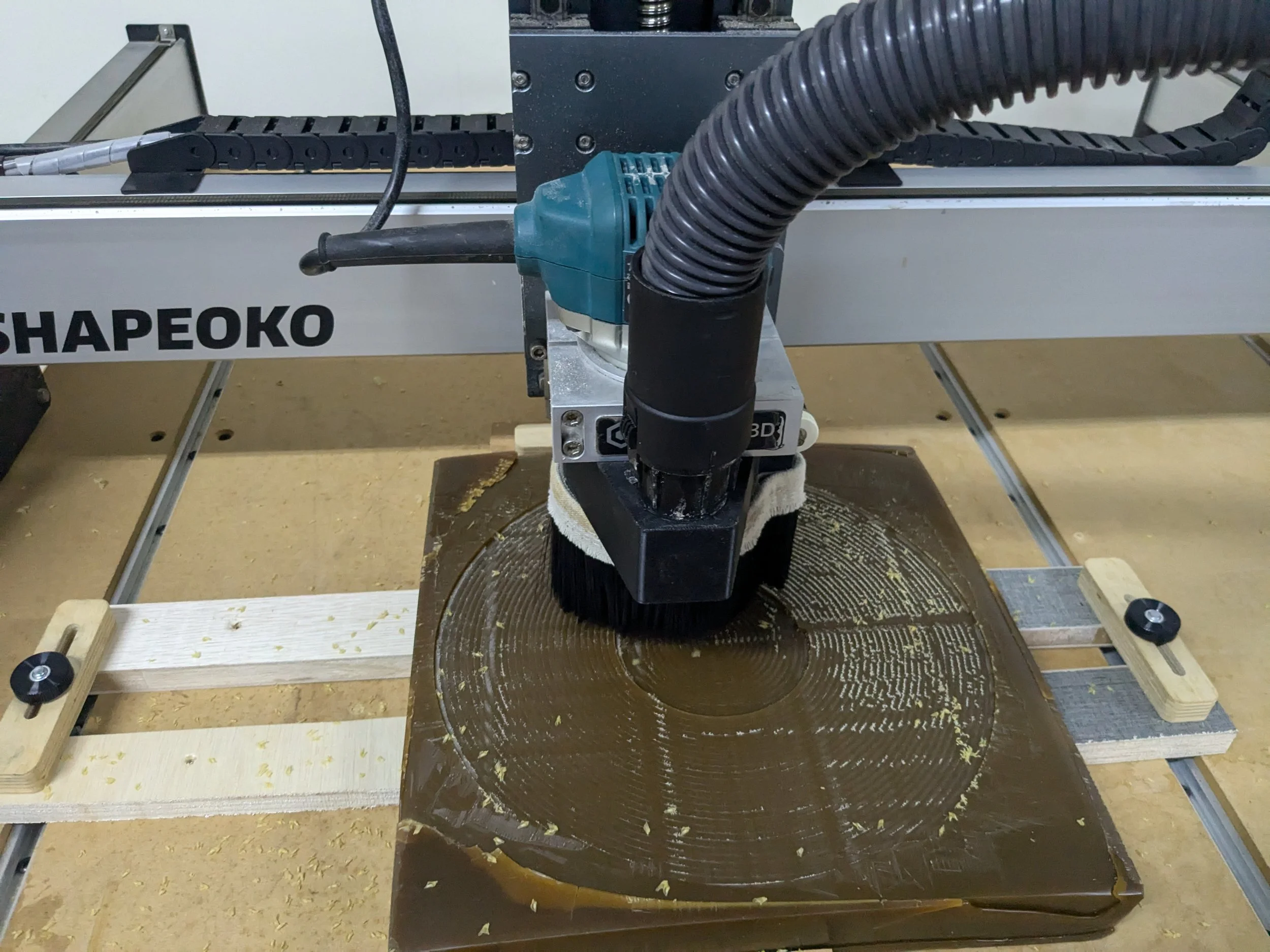

Did you know at Milli, we’re committed to our cause of minimizing the waste that our business produces. To that end, we’ve consciously decided to incorporate wax based moulds for our mycelium production due to it being an excellent alternative to traditional plastic moulds.

We’re taking a more environmentally friendly approach to design and fabrication of our myco-materials. Instead of rigid synthetic moulds, we customize moulds out of wax as it offers a flexible reusable option that can be reshaped, melted, and reformed, greatly reducing material waste that our business produces.

Furthermore, because wax can be sustainably sourced from natural materials like beeswax or plant based alternatives, it aligns with the eco-conscious principle coupled with mycelium based values of creating a fully circular product and solution, using minimal energy production processes from start to finish.

Applying Our Finishing Touches.

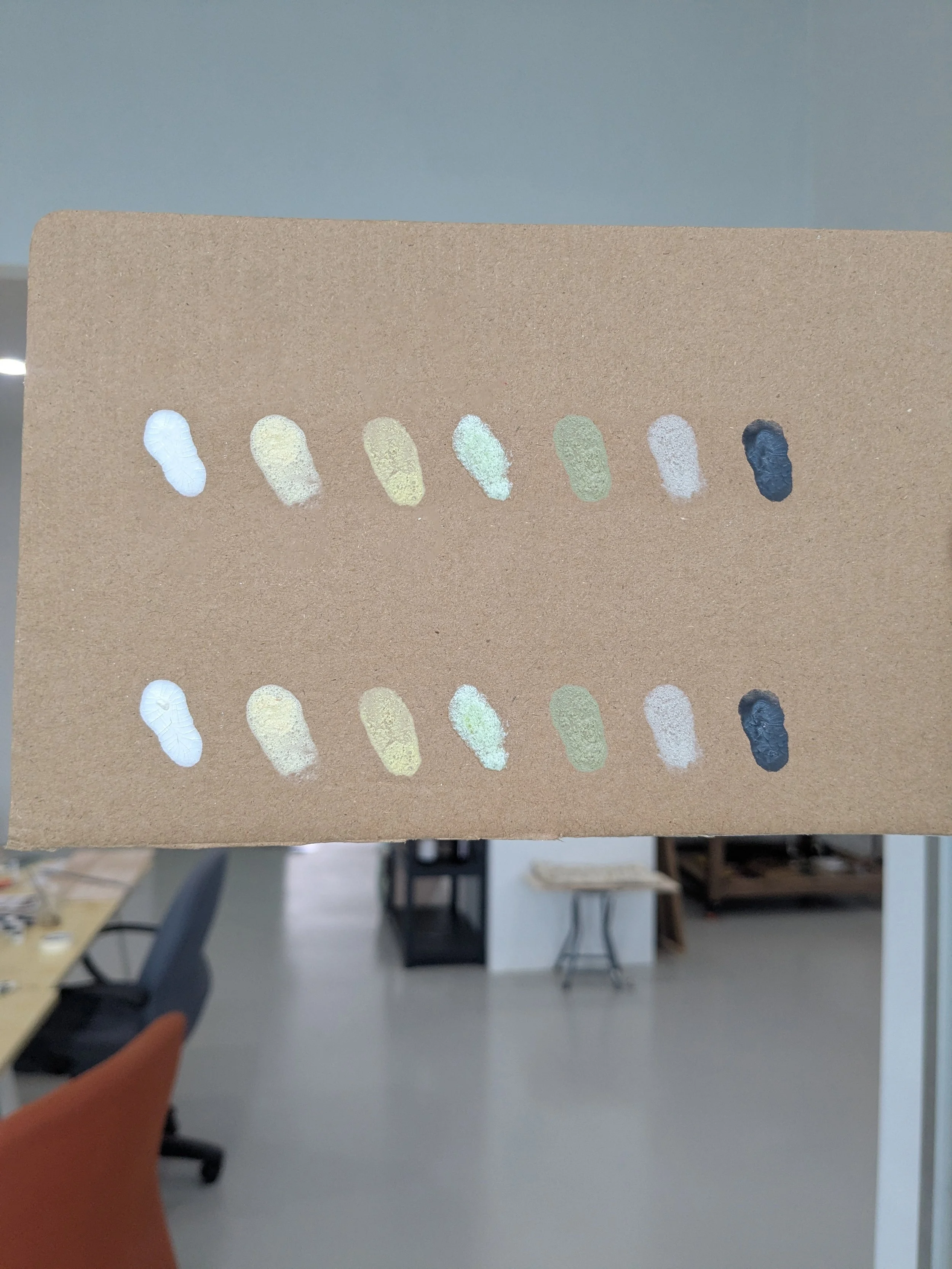

That’s not the end! Applying finishing touches to our mycelium-based materials is an essential step to enhance both their appearance and durability. Natural dyes derived from plants, minerals, or food waste can be used to add rich, warm, earthy tones without compromising the material’s bio-degradability.

While to increase longevity and resistance to moisture or mold, we use our own proprietary blend of eco-friendly coating which aids in helping to create a protective barrier while maintaining breathability. These treatments not only extend the shelf life and functional strength of our mycelium products but also allow room for creative customization!

Event Highlights